GS Yuasa Corporation (Tokyo Stock Exchange: 6674; “GS Yuasa”) today announced that it has installed additional electricity storage systems (“ESSs”) at its Kyoto plant. The ESSs, which were installed in February, were funded with a grant received through GS Yuasa’s participation in the “FY2020 Demonstration Project for the Construction of a Virtual Power Plant that Utilizes Demand-Side Energy Resources”, which was sponsored by the Ministry of Economy, Trade and Industry’s Agency for Natural Resources and Energy.

GS Yuasa has been participating in virtual power plant (“VPP”*1) demonstration projects since FY2016, introducing the use of large storage batteries and conducting verification testing of methods to control them. In FY2017, GS Yuasa installed a container-type ESS at its Kyoto plant and began demonstration testing of its electricity supply-demand adjustment capabilities when controlled based on instructions from a large external storage battery server.

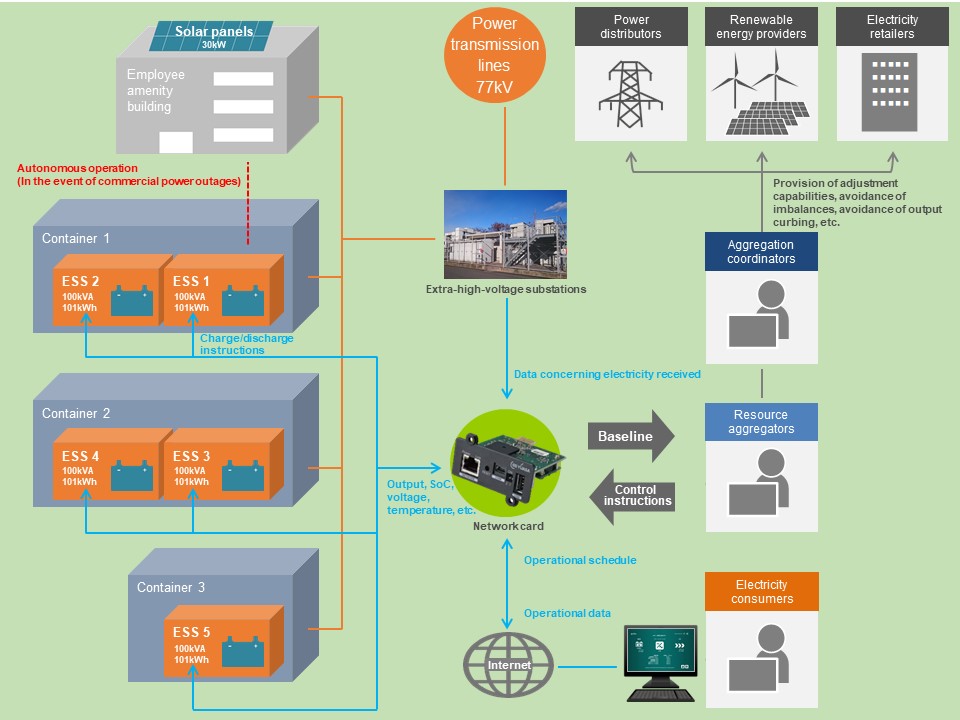

The newly installed ESSs will be used to conduct peak cutting under normal conditions when the power supply is tight in order to further reduce the Kyoto plant’s electricity costs. In the event of commercial power outages, GS Yuasa plans to combine power from the ESSs and existing solar power generation facilities to supply electricity to the plant’s employee amenity building and will use the building to ensure the safety of employees in the event of major disasters. The building will also be used to enhance business continuity functions.

GS Yuasa aims to develop new energy management methods based on linking storage batteries and IoT technologies, facilitate energy use optimization, and further expand the installation of storage batteries at renewable energy power generation facilities, in order to further contribute to the realization of a low-carbon society.

Overview of newly installed ESSs

| Facility name | GS Yuasa Kyoto plant (west precinct) | |

|---|---|---|

| Address | 1, Kisshoin Shinden Sannodancho, Minami-ku, Kyoto City | |

| Construction period | September 2020 to February 2021 | |

| Installed equipment | Power conditioners (LINE BACK Ω ES) | Output: 500kVA (set of 5 at 100kVA each) | Lithium-ion batteries | Capacity: 506.0kWh (set of 5 at 101.2kWh each) |

Features

1. Use of container-based distributed ESSsGS Yuasa power conditioners (LINE BACK Ω ES) each with an output of 100kVA have been installed inside shipping containers and these have been placed in underutilized spaces on the Kyoto plant grounds. Using shipping containers shortens construction periods and reduces installation costs. The use of air conditioning to manage air temperatures in the shipping containers has also helped to enhance the ESSs’ system availability*2.

2. Use of network cards

The ESSs are equipped with network interface cards (NIC)*3 developed specifically for the purpose by GS Yuasa. The NICs communicate with resource aggregators via OpenADR protocol*4 to send baseline data to large storage battery servers. Power conditioner charging and discharging is controlled based on demand response instructions received by large storage battery servers, facilitating control of electricity supply/demand balance.

*1: Virtual power plants (“VPPs”) are systems that utilize IoT devices to remotely control dispersed energy sources such as small-scale solar power generators and storage batteries to enable them to function collectively in a similar manner to a single electric power plant. It is hoped that VPPs will play a significant role as a means to balance power supply and demand through load leveling, absorption of surplus power from excess supply of renewable energy, supplying electricity during power shortages, and so on.

*2: System availability refers to the durability, usability, and operation rate of ESSs when operated in an ongoing manner under normal conditions. “System” refers collectively to the storage batteries, power conditioners, ancillary equipment, and so on that make up ESSs.

*3: Network interface cards are circuit boards that GS Yuasa installs in products it handles (general-purpose/large-scale UPSs, direct current/alternating current power supply systems, power conditioners, lithium/lead-acid battery systems) in order to facilitate networking and communication with external devices and communication with remote monitoring systems.

*4: OpenADR is an automated demand response (ADR) protocol used by resource aggregators in inter-system communications to automatically control demand-side energy devices in order to balance electricity supply and demand.

■Electric power control diagram

■1. ESS containers

■2. The employee amenity building being used to enhance business continuity contingency measures

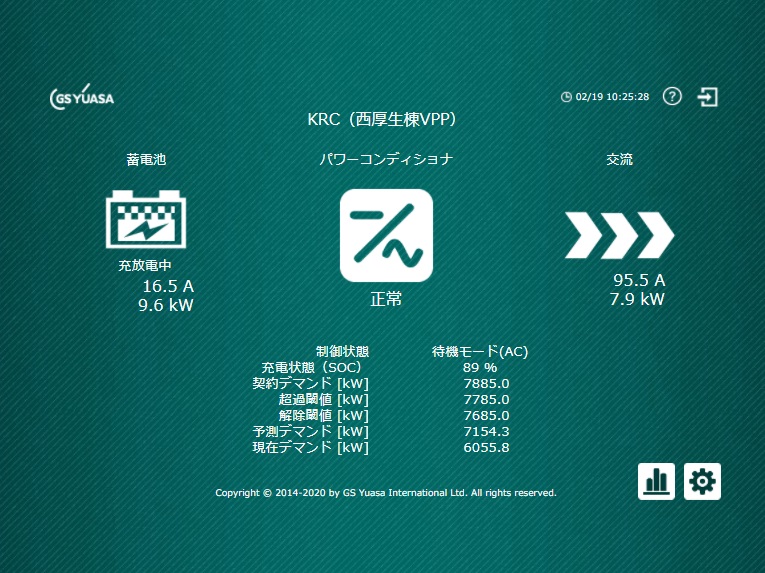

■3. Online user interface screen for remote management system