GS Yuasa Corporation (Tokyo Stock Exchange: 6674; “GS Yuasa”) has delivered two sets of approximately 500kWh lithium-ion batteries and anti-disaster power conditioners for solar power generation to JR Fukushima Station where operations have commenced as a model station for “Ecoste”*1 initiatives being conducted by East Japan Railway Company (Tokyo Stock Exchange: 9020: “JR East”) that involve the adoption of various environmental preservation technologies including energy saving and the use of renewable energy.

Thanks to a power supply system delivered by Mitsubishi Electric Corporation (Tokyo Stock Exchange: 6503), 23% of the power consumed at JR Fukushima Station is provided for by in-house power generation including solar power. Furthermore, the introduction of lithium-ion batteries has enabled power supply to an emergency load providing for a maximum of 12 hours even during power outages due to causes such as disasters, which makes it possible to use JR Fukushima Station as a disaster response facility.

The lithium-ion storage battery system delivered by GS Yuasa for this project uses the lithium-ion battery module “LIM50E-12G” that was developed as a product targeted at uses including smart grids and power storage. As it combines multiple modules, this system can be easilly customized for voltages and storage battery capacities.

Through the spread of power conditioners and lithium-ion batteries, the GS Yuasa Group will contribute to the expansion of disaster response facilities, the building of safe and secure living environments, and a reduction in the environmental footprint.

*1. Ecoste is a plan by JR East that involves the introduction of various environmental preservation technologies including energy saving and the use of renewable energy to the railway stations.

Features of the lithium-ion storage battery system

1. Can be easilly customized for voltages and storage battery capacities through the combination of various modules in a series or in parallel, which enables the establishment of large-scale power storage systems.

2. Through independent control for each bank*2, maintenance is possible without stopping the system.

3. With the standardly-equipped battery management equipment, it is possible to constantly monitor the voltage for all cells, the temperature for all modules, and the current for all units of the lithium-ion batteries, and conduct output to the power conditioner and monitoring and control system.

4. As there is little variance in cell performance and resistance between units, this enables maximum performance as a storage battery system.

*2. One group of multiple lithium-ion battery modules connected in a series in order to gain the prescribed storage battery system voltage.

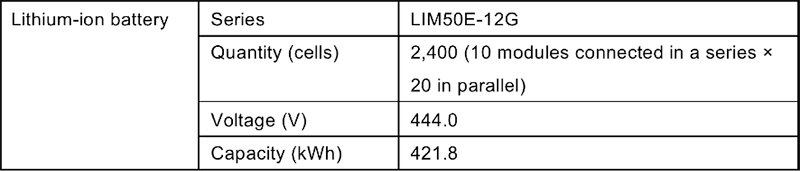

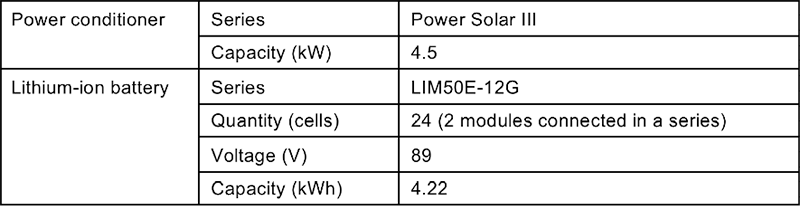

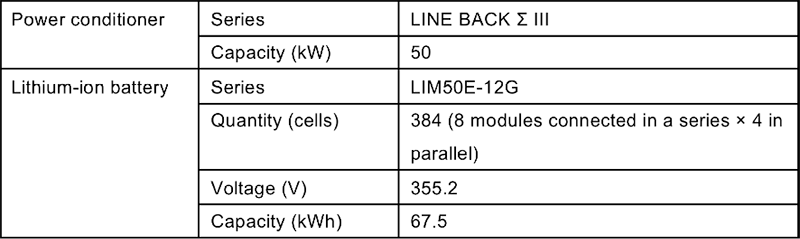

Overview of lithium-ion battery and power conditioner

■1. Lithium-ion storage battery system (for light photovoltaic panels*3)

*3: Photovoltaic panels with a low weight burden on the building and low installation costs because they are lighter compared to standard photovoltaic panels

■2. Anti-disaster power conditioners equipped with lithium-ion battery (organic thin film solar cells*4)

*4: Advanced photovoltaic panels that are ultra-lightweight, allow light to pass through, and have a heat insulating effect through multi-layered glass

■3. Anti-disaster power conditioners equipped with lithium-ion battery (standard photovoltaic panels*5)

*5: Highly reliable weather resistant and corrosion resistant photovoltaic panels that have excellent power generation capacity