GS Yuasa Corporation (Tokyo Stock Exchange: 6674) today announced that subsidiary GS Yuasa International Ltd. (“GS Yuasa”) has successfully completed verification testing of a 400Wh/kg-class lithium-sulfur battery. This achievement was one of GS Yuasa’s interim targets in its R&D work on lightweight storage batteries for aircraft. GS Yuasa is conducting this R&D work as part of the Next-Generation Electrical Propulsion Systems component of the “Research and Development Project for Advanced Aircraft Systems toward Practical Application”* of the New Energy and Industrial Technology Development Organization (NEDO).

The aim of the project, which is now in its third year, is to develop advanced aircraft systems that are highly safe, lightweight, and inexpensive, and hone and refine them to a level where they can be utilized in next-generation all-electric aircraft powered with storage batteries.

GS Yuasa’s R&D work for the project is currently focused on producing the kind of lightweight storage batteries needed for next-generation aircraft through the development of fundamental cell technologies (electrodes, electrolyte solutions, etc.) and efforts to reduce the weight of storage battery management systems and module/pack structures.

Lightweight storage batteries require high levels of mass to energy density. Lithium-sulfur batteries have the potential to replace lithium-ion batteries as an inexpensive high-energy-density alternative because not only does sulfur—the active material—have a high theoretical capacity of 1,675mAh/g, but it is also a cheap and abundant resource. Verification testing of lithium-sulfur batteries has, however, until now been impacted by the following two problems: (1) the utilization rate of sulfur in the electrode reaction decreases because sulfur is an insulating material and therefore achieving a high capacity close to the theoretical capacity is challenging; and (2) the performance of the sulfur positive electrode degrades as a result of the dissolution of reactive intermediates (polysulfides) in the electrolyte solution.

GS Yuasa, together with Kansai University—the subcontractor for the development of fundamental technologies—successfully solved these two problems as part of their R&D work on (1) porous carbon particles used to support sulfur and (2) an electrolyte solution that inhibits the dissolution of sulfur. To solve these two issues, the pores of the porous carbon particles were filled with sulfur and a vinylene carbonate-type electrolyte solution was used to create a stable film on the electrode interface (solid electrolyte interphase).

Moreover, based on these achievements in R&D on fundamental technologies, GS Yuasa has developed a lithium-sulfur battery design and production technology, and conducted small cell feasibility tests. As a result, it successfully demonstrated the performance of a 400Wh/kg-class lithium-sulfur battery (capacity of 8Ah and mass to energy density exceeding 370Wh/kg). Also, as part of its work on developing storage battery control systems and module/pack structures for lithium-sulfur batteries, GS Yuasa has successfully completed the design of a lightweight prototype model and is now commencing trial production and testing.

Kansai University and GS Yuasa plan to present some of these findings and achievements at the “62nd Battery Symposium in Japan” (Nov. 30 - Dec. 2, 2021) at the Pacifico Yokohama convention center (organized by the Electrochemical Society of Japan’s Committee of Battery Technology).

Through the practical application of lightweight storage batteries in the “Research and Development Project for Advanced Aircraft Systems toward Practical Application”, GS Yuasa will contribute to the development of next-generation aircraft and help bring about a sustainable net-zero carbon society.

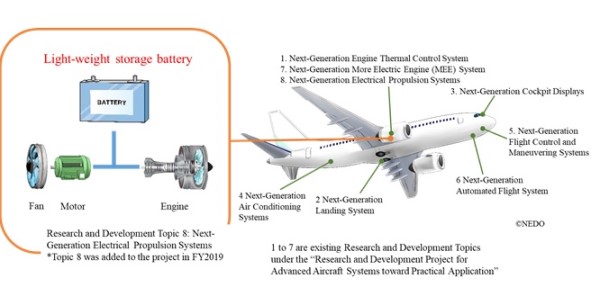

*The project comprises eight R&D topics. The ultimate goal of the project is to create prototype models of advanced aircraft systems and demonstrate, either on the ground or in the air, that these systems provide levels of performance and functionality that are superior to those of existing systems.

■Lithium-sulfur cell (capacity: 8Ah)

■Overview of the “Research and Development Project for Advanced Aircraft Systems toward Practical Application”