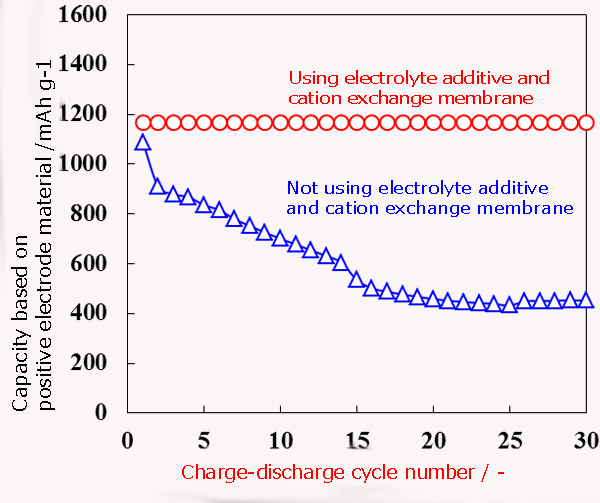

GS Yuasa Corporation (Tokyo Stock Exchange: 6674; “GS Yuasa”) succeeded in significantly

improving the charge-discharge cycle performance of lithium-sulfur battery, which has metal lithium as

the negative electrode material and a sulfur-porous carbon composite as the positive electrode

materialNote1as shown in Figure 1.

The improvement achieved in the cycle performance of lithium-sulfur battery means the substantial

progress GS Yuasa has made towards practical use of silicon-sulfur battery*1, which has 3 times higher

energy density than that of conventional lithium ion battery. We will accelerate development of

technology for practical use of silicon-sulfur battery with its cycle performance improved further by using

silicon based material for the negative electrode from now on.

Sulfur used in this battery is much expected as the positive electrode material for the advanced lithium

ion battery, because of low cost, abundance as a resource and low environmental hazard, in addition to

its extremely high theoretical capacity (1675 mAh g-1 Note 2) compared with conventional positive

electrode materials for lithium ion battery.

It is yet to be commercialized, however, because polysulfide as an intermediate created by discharge

reaction in the positive electrode, easily elutes out from the electrode due to its high solubility to

electrolyte and the eluted polysulfide repeats the oxidation-reduction reaction between the positive and

negative electrodes causing self-discharge and resulting in significant capacity decline along with

charge-discharge cycle.*2

GS Yuasa prevented the elution of polysulfide by using electrolyte additive and the self-discharge with

polysulfide’s transfer between the positive and negative electrodes by using cation exchange membrane

Note 3 as a separator. As a result, we succeeded in suppressing capacity decline along with the

charge-discharge cycle in lithium-sulfur battery using such materials, without losing the capacity of the

sulfur-carbon composite as the positive electrode material. In other words, we succeeded in significantly

improving its charge-discharge performance.

GS Yuasa will continue to contribute to the realization of a low carbon society through development of

the new advanced lithium secondary batteries with even higher energy density.

*1 In November 2014, GS Yuasa announced the achievement of 3 times higher energy density of

silicon-sulfur batteryNote 4 based on the positive and negative electrode materials than that of the

conventional lithium ion battery (the lithium ion battery for electric vehicles sold by GS Yuasa) and

the schedule to ship samples of such battery in 2020.

*2 Till now, combining polymer and sulfur was proposed as a technology to control elution of

polysulfide but that was not complete and not only cycle performance remained at low level but

also the capacity based on composite as the positive electrode material remained below 800 mAh

g-1 as the content rate of sulfur reduced due to combining the polymer.

[Terminology]

Note 1: ‘Sulfur–porous carbon composite’ positive electrode material

Material that has 8 times higher capacity (1000 mAh g-1) than that of the conventional positive electrode material for lithium ion battery .

Capacity here refers to the amount of electricity that can be obtained from 1g of electrode material.

Note 2: mAh g-1 (milliampere hour per gram)

Unit for capacity. It is also expressed as mAh/g.

Note 3: Cation exchange membrane

Polymer membranes that selectively passes cation (atoms that are charged positively such as Li ion).

Note 4: Energy density based on positive and negative electrode material

Energy density calculated from the mass of electrode materials alone excluding battery parts such as the battery case, current corrector, separator and electrolyte.

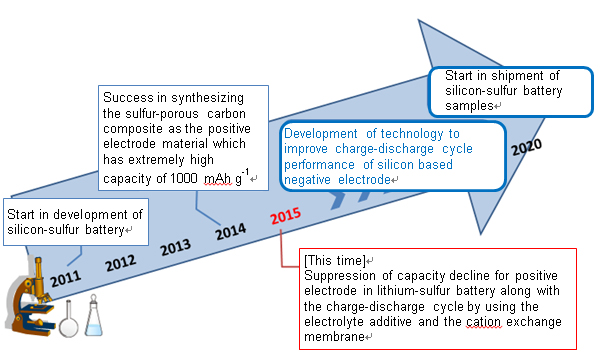

■[Figure 1] Charge-discharge cycle performance of lithium-sulfur battery

■[Figure 2] Image of silicon-sulfur battery commercialization