GS Yuasa International Ltd., Tokyo Stock Exchange: 6674; “GS Yuasa”, has completed initial development of a new advanced lithium secondary battery which has a “Sulfur - Porous Carbon Composite” positive electrode with 8 times higher capacity 1) than that of conventional lithium ion battery 2) positive electrodes and a silicon based negative electrode with high capacity as shown in Figure 1. The energy density with respect to material amount of both electrodes 3) for new battery is approximately 3 times higher than that of conventional lithium ion battery judging from discharge performance that we obtained by experimental. This technology will allow the driving range of electric vehicles to significantly increase. The practical technology development will be preceded by further improvement of durability performance for the silicon based negative electrodes, so that we expect its samples to be available by 2020.

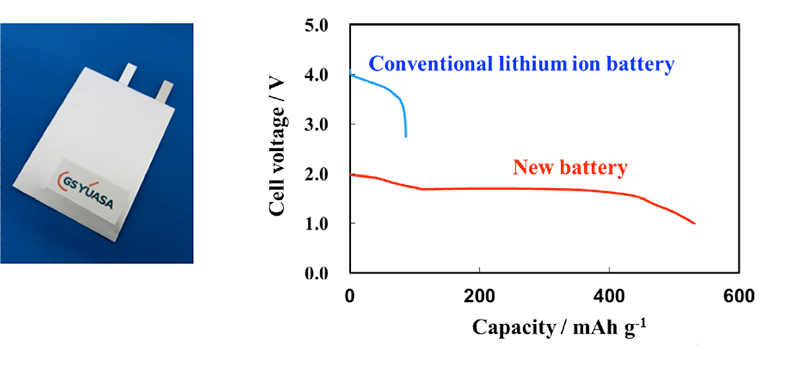

The extremely high energy density is primarily the result of the new sulfur composite positive electrode. Sulfur is one of the most promising materials for the positive electrode in advanced lithium secondary batteries because of its high theoretical capacity of 1675 mAh g-1 4) in addition to low cost and natural abundance. However, practical utilization of the sulfur for the electrode reaction is low because of its insulating nature 5). As a result, it is difficult to achieve actual capacity as high as the theoretical one. To improve the utilization, currently the standard approach has been attempted using a high conductive porous carbon matrix 6) to support the sulfur component of the electrode. However, the capacity of the positive electrode has been shown to remain below 800 mAh g-1 due to challenge in developing a uniform carbon matrix in which the sulfur can be fully utilized.

GS Yuasa has worked to improve this issue and has successfully synthesized a “Sulfur - Porous Carbon Composite” positive electrode with a capacity of above 1000 mAh g-1 by infusion of sulfur into a controlled nano-sized 7) and uniform pore in the matrix as shown in Figure 2.

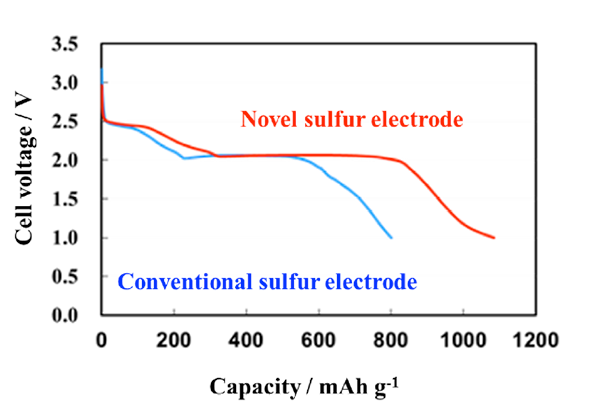

A second challenge in the development of sulfur based positive electrodes has been poor life performance due to the dissolution of polysulfides produced during discharge process, which results in a short life for the cell. GS Yuasa has developed a technology to minimize this dissolution, which has resulted in better life performance than that of current one. We drastically suppressed capacity decrease of the positive electrode with the composite by using the technology as shown in Figure 3.

GS Yuasa is committed to contributing to reducing the carbon footprint of our customers through the development of technologies that benefit society.

※A part of this achievement of “Sulfur - Porous Carbon Composite” was reported at “The 55th Battery Symposium in Japan organized by “The Committee of Battery Technology / The Electrochemical Society of Japan” held on November 19 – 21, 2014 in Kyoto, Japan.

【Glossary】

1) Capacity

Amount of electricity obtained from 1 g of electrode material

2) Conventional lithium ion battery

Available commercial lithium ion battery by GS Yuasa International Ltd. for electric vehicles

3) Energy density with respect to material amount of both electrodes

Energy density based on amount of only materials of both positive and negative electrodes excepting battery case, current corrector and electrolyte

4) mAh g-1 ”milli-ampere hour per gram”

Unit for capacity

5) Insulating nature

Nature that highly resists electricity

6) Matrix

Material fixing another material

7) Nano-size

Distance from 1 nm to 9 nm

1 nm = 1/million of 1 m = 1/thousands of 1 μm

※Thickness of the hair: 50-100 μm

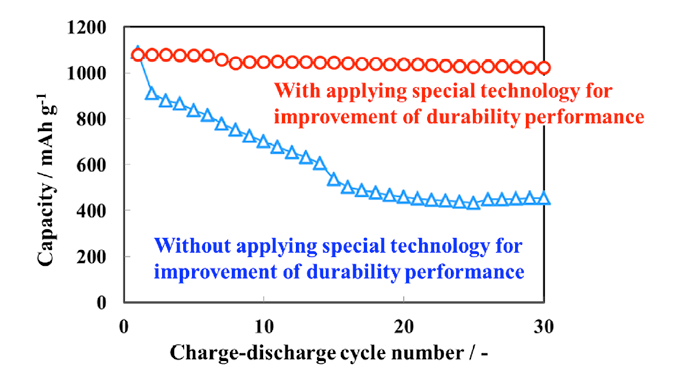

■Figure 1. Photo of test cell with sulfur - porous carbon composite positive and silicon based negative electrode of 12 cm2 surface, and discharge performance for the cell. Capacity calculation is based on material amount of both positive and negative electrodes.

■Figure 2. Discharge performances for test cells with sulfur - carbon composite positive electrode and stable lithium metal negative electrode. Capacity calculation is based on material amount of the positive electrode.

■Figure 3. Durability performances for test cells with sulfur - porous carbon composite positive electrode and a stable lithium metal negative electrode. Capacity calculation is based on material amount of the positive electrode.